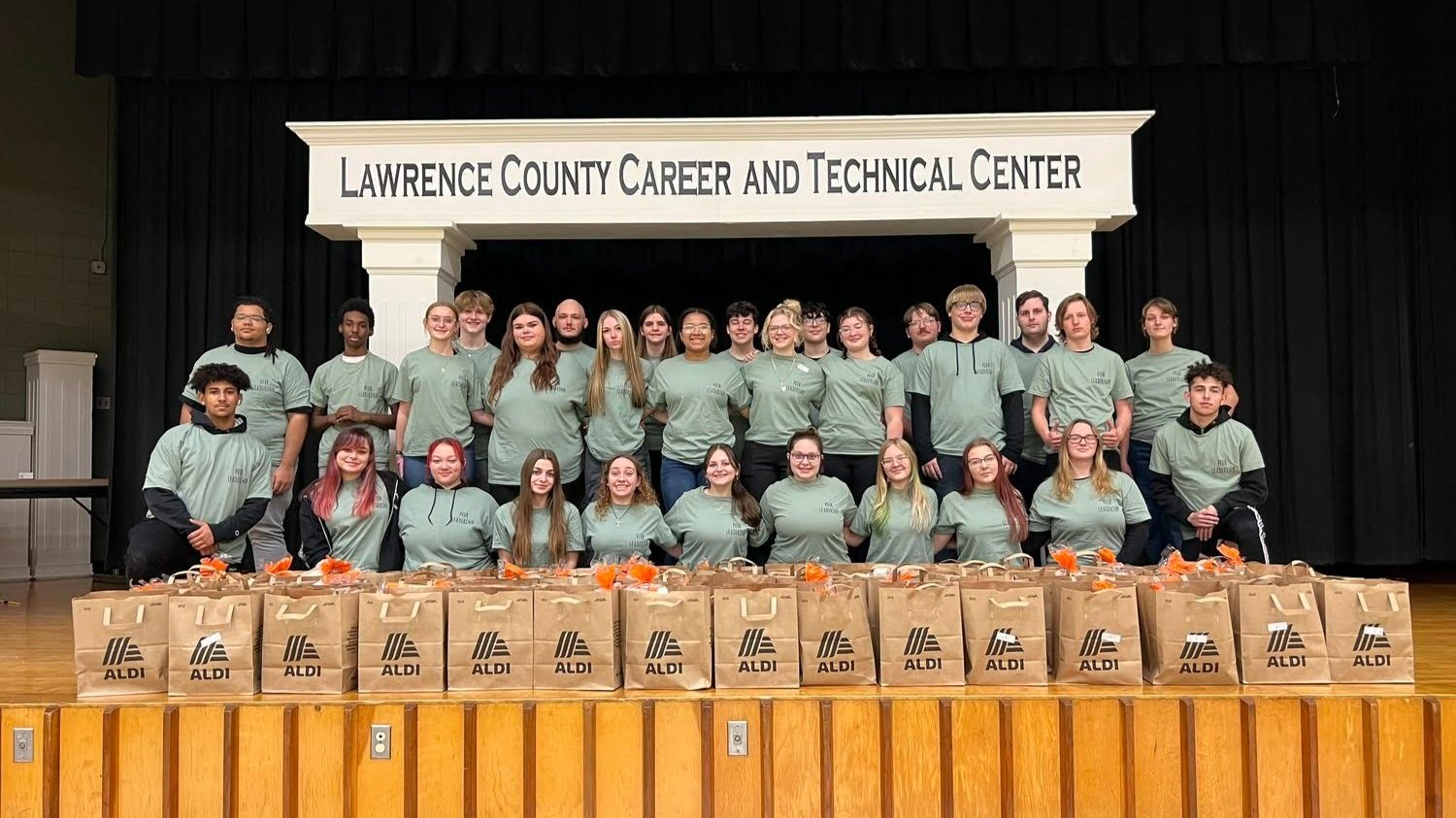

Welcome to the Lawrence County Career & Technical Center website!

The LCCTC is located at 750 Phelps Way, New Castle, Pennsylvania. The LCCTC is a technical educational institution founded in 1969 to meet the needs of the community and eight secondary sending schools in Lawrence County. The mission of LCCTC is to provide quality career-technical education programs and services that prepare youth and adults for success in the workplace, post-secondary, and community, now and in the future. For more information about the LCCTC, please visit our news page, events page, and about LCCTC page today!

School Calendar

Welcome Packet

Safe 2 Say Something

Bell Schedule

Courses at LCCTC

School Contact Info

Student Handbook

Career Portfolio

Economic CTE Recovery

Chromebook Handbook

LCCTC SkillsUSA

LCCTC Yearbook Order